Products Products

Machinery for Machinery for

textil finishing textil finishing

|

|

Products

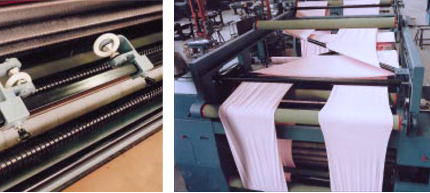

RAISING AND NAPPING MASTERFELP

The MASTERFELP Raising-Napping machine is the result of a long and arduous research and development program carried out by FONTANET's technical staff since 1919. This model was created after the popular SIMPLAFELP, the MASTERFELP Raising-Napping machine is very well-equipped giving good production, easy running and low maintenance. More than 500 machines are running in 34 countries, with great results.

SPECIFICATIONS

- Equipped with card clothing for both Counterpile or Pile/Counterpile.

according to the articles to be processed.

- Control of the raising cylinders' speed and fabric tension using specially designed, fully reliable variable extendible pulleys.

- Movement transmission shafts fitted with speed reducers with long life, silent helicoidal gears.

- Machine starting and stopping via progressive acceleration/deceleration.

- Cleaning cylinders for the card clothing, easily synchronisable.

- Fabric transport cylinders driven by AC motor.

- Possibility of changing and sharpening the card clothing while still fitted on the machine using a simple optional device. |

CONTROL PANEL

Maximun accuracy digital readouts.

- Energy regulators for raising (Pile and Counterpile) allowing '0 point'.

- Fabric tension regulators (Input and Output).

- Fabric speed regulator.

- Clock -giving run- time readout in hours.

- Lubrication and preventive maintenance indicators.

- Warning displays.

- Safety stop. |

ACCESSORIES

- Driven stretching cylinders for open

knitwear.

- Ring expanders for simultaneously

working 2 pieces of tubular knitwear.

- Crossed bars for turning the fabric face inside out for raising on both sides.

- Crossed bars for turning inside out and handling 2 pieces of tubular knitwear being worked at the same time.

- Heating cylinder at input for giving temperature prior to raising using steam or electrical resistances.*

- Centring device or fabric guides at

input.*

- One or two fabric outputs from the

drum to eliminate tensions and avoid shrinkage.*

- Fabric brushing cylinder at the output.*

- Micro-processor with 400 memories of the main raising parameters.

- Computer with software for control of production, statistics, machine stoppages, etc.

- Device for wiring and sharpening of the card clothing while still on the machine.

- Pontcard tool for fitting the card

clothing.

- Grindstone for sharpening the card

clothing.*

- Automatic compensator for synchronising 2 raising machines.

- J-Box for synchronising 2 raising machines.

- Input-Output for giant roll (1800 mm maximun diameter).

- Drum reverse spin. *

* Accessories used on specialized

applications. |

|

|

|

|